Home » Shop Products » Engineer Tools & Spares » Ultrasonic Testers » Portalevel® Max Plus

PRODUCT CATEGORIES

Portalevel® Max Plus

Brand New Portalevel® Max Plus Flagship Ultrasonic Liquid Level Indicator with Extended Calibration Features

The Portalevel® Max Plus is an all-new liquid level indicator. It has three extended calibration features and a display that will indicate if the sensor is in the GAS or LIQUID phase of a fire suppression cylinder. This portable and battery powered, liquid level indicator designed to non-invasively, accurately, and reliably measure the level of fire suppression agent contained within a cylinder. The UL-Approved Portalevel® Max Plus is suitable for CO2, most Liquified Clean Agents and Halons.

Ultrasonic level indicator

Portalevel® Max Plus Overview

One of the latest additions to the Portalevel® range, the all-new Portalevel® Max Plus offers vast improvement to the functionality and display. All packaged into a smart, ergonomic, and rugged enclosure. With the implementation of three calibration modes, the user has much greater control when testing a large variety of liquids and fire suppression systems. A new user interface upgrade now indicates which phase the sensor is placed, indicating either GAS or LIQUID.

- User-friendly display, versatile and accurate to ±1.5 mm.

- Three intelligent calibration features and four power settings for increased gain.

- Capable of testing a wide variety of fire suppression agents, such as; CO2, FM200™, NOVEC™ 1230, old Halon agents, FE-13™, FE-25™, NAF S III™ and all core Clean Agent systems.

The Portalevel® Max is designed to be a portable way to non-invasively locate the liquid level inside most single skinned cylinder. Our technology is suitable for many applications, but it is most widely used as a replacement to both weighing fire suppression cylinders during installation and servicing. Or additionally as a replacement for the fitting of internal and invasive liquid level ‘float’ devices. Once the liquid level height inside a container has been located, the agent weight can be determined using the Portasteele® Calculator. This is designed to quickly convert liquid height to agent weight accounting for the cylinder size, agent type and temperature.

Converting Liquid Level to Weight

Monitoring the liquid level in fire cylinders is a vital aspect of any fire suppression system maintenance schedule. However, understanding how the liquid level relates to the fill weight of the cylinder is equally important. Coltraco Ultrasonics offer, in conjunction with the Portalevel® range, the world’s first liquid level to agent mass calculator.

The Portasteele® Calculator calculates the agent weight of a fire suppression cylinder. It does this by using the liquid level determined by our Portalevel® range or inversely, by using the required fill level for a certain weight of suppression agent. The Portasteele® Calculator is sold as a stand-alone unit on a 7’’ hand-held tablet to be used in conjunction with our Portalevel® range.

Operating Principle

- An ultrasonic transducer, coated in ultrasound gel (or water) generates an ultrasonic pulse that is transmitted into the fire cylinder and is reflected back. The ultrasonic gel acts a couplant by removing any air gaps between the ultrasonic transmitter and the cylinder wall, thus allowing the transmission of ultrasound.

- As the wave travels throughout the cylinder, some of its energy is dissipated into the cylinder and its contents. This results in the signal returned to the transducer having decreased amplitude. Analysis of the returned signal can be used to determine if the transducer has been placed in the liquid or gas phase.

- The Portalevel® Max Plus will display a numerical value which is an indicator of the strength of ultrasound received by the unit.

- The device is calibrated by moving the transducer up and down the cylinder whilst reading the numerical value off the display and engaging the ‘CAL’ button when in the appropriate section.

- The user has the option of selecting between three calibration modes depending on the cylinder and agent type.

- The Portalevel® Max Plus will now indicate which section of the cylinder the ultrasonic transducer is located by displaying GAS or LIQUID, thus allowing the user to accurately find the liquid level.

What’s in the box

Portalevel® Max Plus Unit: main electronic unit fitted with harness points for handsfree operation.

Handheld Ultrasonic Sensor: fitted with magnetic head to ensure perfect positioning on the cylinder wall every time.

Ultrasonic Gel: ensures perfect connection between cylinder and sensor allowing the transfer of ultrasound into the inspection surface.

Carrying Case: robust protective case which is ideal for transportation, storage and protection in harsh environments.

Infrared Thermometer: used to measure cylinder surface temperature.

Calibration Certificate: providing traceability of accuracy and documenting unit setup.

Operating Instructions: manual provides setup instructions and step-by-step guide for usage. Technical support is available for the lifetime of the product.

See the full Coltraco range HERE

Frequently asked questions

What agents can the Portalevel® MAX Plus measure?

How accurate is the Portalevel® MAX Plus?

What are the three calibration modes used for?

What cylinders can the Portalevel® MAX Plus measure?

Do I need specific ultrasonic gel?

Can I use the Portalevel® Max Plus on CO2 above 31°C?

Will high temperatures affect other fire suppression agents, such as Clean Agents?

My cylinder has a siphon tube inside, can I still use the Portalevel® Max Plus?

By Coltraco

|

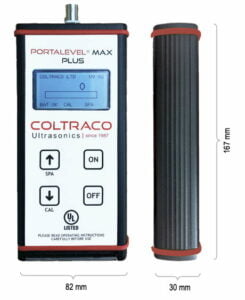

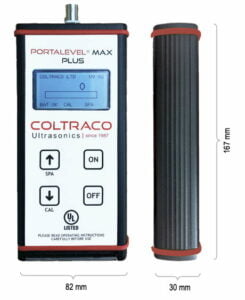

Dimension | Height: 167mm, Width: 82mm, Depth: 30mm, Weight: 300g |

| Accuracy | +/- 1.5 mm / +/-1/16 inch | |

| Sensor | 14mm diameter magnetically mounted sensor applicator. | |

| Sensor Frequency | 1 MHz | |

| Sensor Connectivity | 1 m BNC coaxial cable. | |

| Power supply | 1 x PP3 9V battery offering 10 hours operational battery life. | |

| Display | 55 x 28 mm backlit LCD. | |

| Operating temperature | -10 °C to +65 °C / 14 F to 149 F | |

| Classifications & Approvals | UL Listed, RINA Classification Society Approval, ABS Type Approval | |

| Enclosure Rating | IP65 Rating | |

| Registrations | UKCA CE ISO 9001, ISO 14001 | |

| Warranty | Main Unit: 3-Year Warranty | |

| Sensor: 1-Year Warranty | ||

| Technical Support: Lifetime of the unit |